Asset Performance Integrity

ANTEA asset performance integrity software empowers organizations to manage integrity, reliability, and functional safety - while optimizing maintenance, reducing risk, and supporting compliance

It gather all legacy data from disparate sources — from P&IDs or spreadsheets to paper reports — and consolidate it into one digital easy-to-use database.

The system seamlessly integrates with existing ERP/CMMS/SAP systems you currently use, aligning all data for a single version of the truth.

Cloud-Based Asset Library with 3D Digital Twin

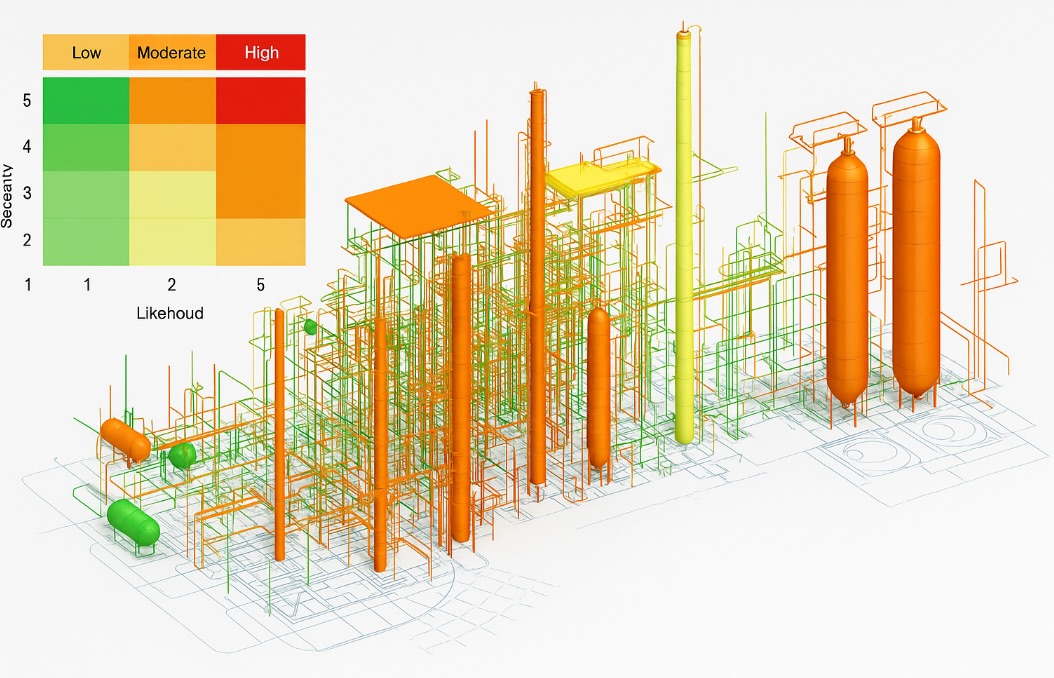

Risk Based Inspetion (RBI) Software for 581

Perform qualitative, semi-quantitative and quantitative analyses to evaluate the probability and severity of failures in your plant. Leverage our industry-leading digital twin technology for interactive visualization – including a dynamic, virtual replica of your plant. RBI data is overlaid onto the digital twin and colored by risk level, providing an instant overview of asset health.

Inspection Data Management System (IDMS) with Digital Twin

IDMS Applications and Benefits

Maintenance Planning and Scheduling

- IDMS provides operators with a comprehensive overview of asset conditions, enabling them to proactively schedule maintenance and repair activities. This approach can minimize downtime and extend the lifespan of assets.

Risk Management and Mitigation

- IDMS helps identify and prioritize inspections for assets posing significant risks to operations. This allows for the allocation of resources and prioritization of maintenance tasks to address safety hazards and prevent asset deterioration or equipment failure through preventive maintenance measures.

Compliance and Regulatory Reporting

- IDMS facilitates automated report generation and meticulous documentation in accordance with major regulatory standards like API, ASME, OSHA, and ISO. Compliance with these standards demonstrates preparedness for regulatory audits.

Performance Analysis

- IDMS offers valuable insights into asset performance, allowing operators to optimize maintenance strategies and identify opportunities for system improvements.

Improved Efficiency

- IDMS software centralizes all data inputs into a single database, streamlining maintenance processes, reducing downtime, and boosting productivity. This ensures that all relevant departments have access to the same accurate information, facilitating quick access to actionable insights and informed decision-making.

Cost Savings

- With IDMS, operators can identify potential issues promptly and schedule proactive maintenance activities, avoiding costly repairs and replacements. Additionally, smarter inspection planning leads to a reduction in unnecessary asset examinations, resulting in overall maintenance cost savings.

Integrity Operating Windows

Integrity Operating Windows (IOWs) provides predefined limits on damage mechanisms that can affect an asset’s performance. When operating variables exceed these limits, an asset might be approaching conditions that could lead to preventable damage and failure.

Within an asset integrity management (AIM) software, IOWs operate as an early and instant warning system. The AIM software sets the limits, monitors the asset, and instantly notifies you when a variable approaches the limits of the IOW.

This makes it possible to address the issue before it becomes a concern for asset failure, unplanned shutdown, or process safety

Pipeline Integrity Management from Construction to Decommissioning

Pipeline integrity management system (PIMS), also known as pipeline integrity management software, refers to the software platform used to manage pipeline integrity. The objective of a PIMS is to optimize operations, prolong lifecycles, and prevent incidents. The type of integrity data managed includes a pipeline’s inspections, maintenance, corrosion monitoring, pressure testing, discontinuity and soil evaluations, and more – all while ensuring adherence to stringent and constantly evolving regulations on pipeline operations